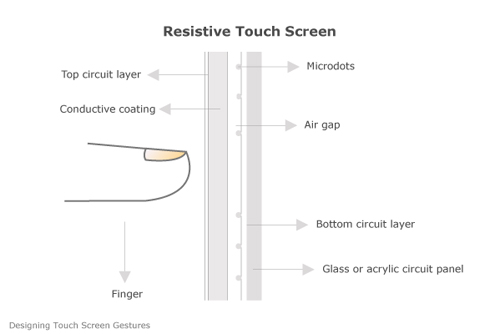

Resistive touch screen is made of two most important conductive layers. These layers are electrically conductive and separated from air gaps or microdots. When a finger or any other object (e.g. stylus) touches the outer layer of touch screen, the connecting points of two layers act as a voltage divider. In simpler language, when a finger or any other object (e.g. stylus etc.) touches the outer layer of the touch screen, there is a notified change in electric current at the connecting point of two conductive layers, which eventually is registered as a touch point.

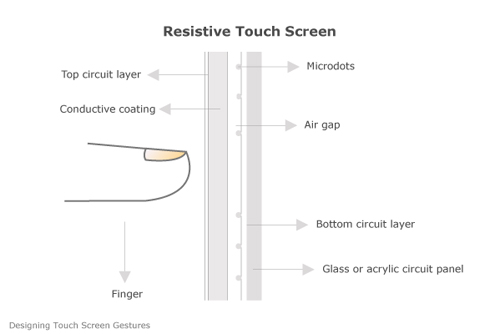

The two conductive sheets have horizontal and vertical lines. When finger or any other object touches the outer layer of the touch screen, the lines help detect the x and y position, eventually helping register the precise location of touch.

Figure showcasing the internal structure of resistive touch screen.

Figure showcasing the internal structure of resistive touch screen after the finger pressed.

Resistive touch screen can be used with finger or stylus. It is not limited to a human finger touch. It is beneficial to use in cold environments where people wear gloves to interact with monitor. Resistive touch screens are sufficiently accurate for usage in shopping malls, ATMs; touch screen kiosks etc., though the endurance (number of touches) is relatively less.