Design Resource

Baajuband - Belgaum

Traditional Gold Jewelry

by

Prof. Bibhudutta Baral, Divyadarshan C. S., Lija M. G., Shruti K. and Smitha S.

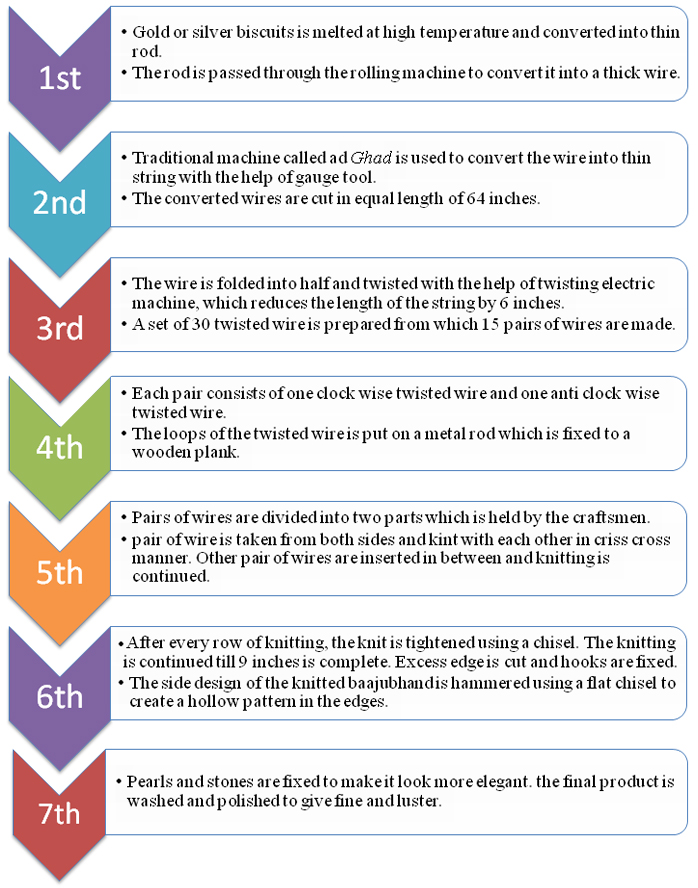

Baajuband is a traditional ornament made of gold wire. Basically, it is a gold ornament but with the change of time and cause of an increase in gold rate, this ornament is also made in silver and copper, which is coated with gold. Gold biscuits are melted and converted into a piece of thick stick (5-8 millimeter). This stick is then passed through a rolling machine, which converts the gold stick into the thick wire (3-5 millimeter). The thick wire is attached to a traditional machine called “Ghad” (In the Marathi language) to convert the thick wire into a thin gold wire. The machine consists of two levers on both side and gauge plate holder in the middle. One end of the gold wire is rotated to one side of the lever and the other end of the wire is pulled through the gauge plate into the thin gold wire. The process of wire pulling is repeated until the required size of 0.75 millimeters of the gold wire is achieved.

The converted thin wire is washed in acid and normal water to remove the impurities. Wires are cut into the equal length of 64 inches and then again folded into half which brings the length down to 32 inches. The folded wire is attached to an electric motor which helps to twist the folded wire with each other. The twisting process reduces the length by 6 inches. It requires 30 twisted gold wires to create one medium size Baajubhand. Before twisting, 30 gold wires are divided into two parts. The fifteen wires are twisted clockwise and the other fifteen is twisted anti-clockwise. From the 30 twisted wires, 15 pairs of wires are made. Each pair consists of one clockwise twisted wire and one anti clock twisted wire. This is done to create the design while knitting the strings. A metal rod is passed through one end of the twisted wire’s loop and fixed to the wooden plank. The pairs of wires are divided into two parts, one to the left and one to the right. Either side of the strings is held by the artisan’s feet. Artisan takes a pair of string from both sides and starts knitting or weaving them in a criss-cross manner. After every row of knitting, the chisel is used to tight the knit. This process is continued until 9 inches of knitting is done. The excess wire edges are cut using a cutter and hooks are added in the end. The edge of the knitted strip is hammered with the help of flat chisel to create a hollow pattern in the edges. The knitted strip or belt is decorated with stones and pearls to make them look more elegant.

Baajuband is also made with silver and copper wire. To make silver article it is the same process as made for the gold articles. To make copper strip the wire is purchased from the local market. The copper strings are then cut and twisted. The twisted copper wires are heated to remove the chemical coating on them and the washed in acid. The twisted copper wires are then knitted into a 9-inch strip same as the gold or silver strips. The silver and copper knitted strips are gold plated after completion. Artisan of Belgaum weaves the design with copper or silver wire and sends them to Mumbai for gold plating. Other decorative items like stones and pearls are also added to make them look beautiful which completes the process. Baajuband products are sold in Belgaum and different parts of India.