Design Resource

Bamboo Curtain - Alleppey, Kerala

Window Coverings

by

Prof. Bibhudutta Baral and Ranjitha M. C.

Bamboo has played an important role in the development of mankind. Bamboo is used in wide range both as a woody material and also as food. Bamboo is a light, strong, versatile and environment friendly. In Kerala, there are 28 species of bamboo and the main species are Bambusa bamboos, Ochiandra Travancorica, Dendrocalamus Strictus and Dendrocalamus Stocksii. Kerala has a large number of thin-walled bamboos called reed bamboos which are used mainly for weaving by the traditional artisans. The bamboo pole is cut vertically to obtain vertical strips. The sliced strips are dried in sun sunlight and the edges of the roughly sliced bamboo strips are smoothened. The smoothened bamboo strips are soaked in chemical water for three to four days and again dried in sunlight for durability.

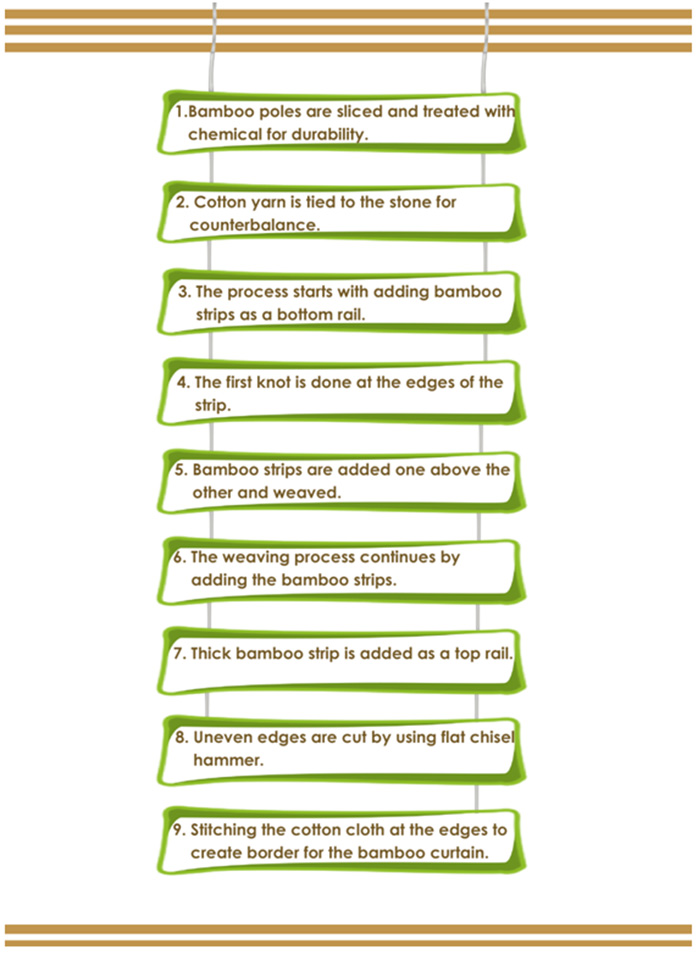

Bamboo strips are the basic material for bamboo curtains. Once done with the bamboo slicing, the next step is tying the cotton yarn to the stone at the end of the yarn for counterbalance and the length of the cotton yarn is depends on the size of the curtain which has to be weaved to get the stiffness and to tighten the weaved thread. Then the stone is slung on a stand made of bamboo poles. The process starts by adding a bamboo strip around three inches in width as a bottom rail and starting to weave. Whereas the first knot is done at the edges of the strip so that the bamboo strip will be in a particular position. Then the small bamboo strips are added one above the other and weaved by rotating the cotton yarn ends vice-versa so that the bamboo strands get locked within the cotton yarn and the process continues. Then the thick bamboo strip is added as a top rail and the edges are cut by hammering the chisel. Once done with the weaving, the artisan starts to stitch the cotton cloth at the edges to create a border for the curtain using needle and thread.

Flow Chart: