Design Resource

Coconut Shell Craft - Alleppey, Kerala

Incense Holder

by

Prof. Bibhudutta Baral and Manasa K. H.

The process of coconut crafts involves sketching, cutting, sanding, and buffing to create the finished product. The process involved in sourcing the coconut shell for the finished product has undergone drastic changes. Initially, hand tools were used to carve, cut, and finish the edges. With the advent of machines, there are lathe machines that have replaced all the hand tools. The process is much faster.

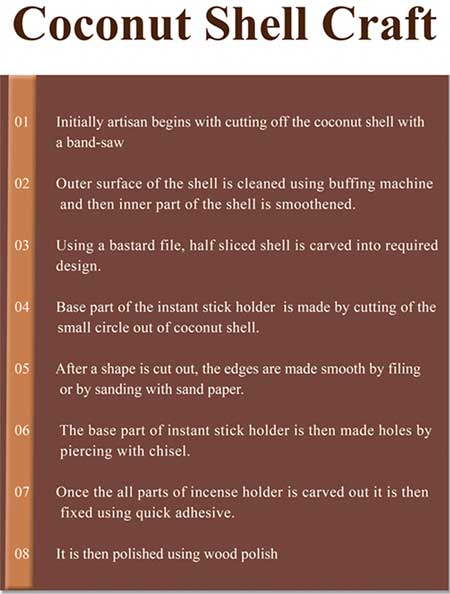

Initially, the artisan begins by cutting off the coconut shell with a band-saw to reveal the interior of the coconut and Scoop out the flesh of the coconut with a chisel. It should be dry and easy to remove. At each stage, sanding is done to make the surface smooth. Finally buffing is done for the inside surface in case of a hollow product or serving bowl.

The edges of the coconut shell are made smooth by filing or by sanding with sandpaper. This process is followed repeatedly till the finish is satisfactory. The outer surface of the shell is cleaned using a buffing machine and then the inner part of the shell is smoothened. Using a bastard file, then half sliced shell is carved into the required design. Once the shell is given a design it is when they start working on the base part of the instant stick holder by cutting the small circle out of the coconut shell. To make the base part of the instant stick holder initially they clean the outer and inner surface of the coconut shell using a buffing machine and emery sheet. Once the surface is cleaned circle kind metal tool is hammered placing over the center coconut shell.

After a shape is cut out, the edges are made smooth by filing or by sanding with sandpaper. The base part of the Incense holder is then made into holes by piercing with the chisel. Once all parts of the incense holder are carved out it is then fixed using quick adhesive. It is then polished using wood polish. Alternatively, if a glossy finish is desired, it is given a coat of synthetic varnish. If the surface is to have a dark finish then it is painted before the varnish coat is applied. The inside of the object in this case is first rubbed with sandpaper to get the desired smoothness and then it is buffed on the machine.

Flow Chart: