Design Resource

Glass Making - Purdilnagar, Uttar Pradesh

Glass - The Exquisite Material

by

Bangles, often called “Choodi” in Hindi are traditionally worn by women to symbolize matrimony. Purdilnagar is one of the main centers for making of bangles using an open furnace method.

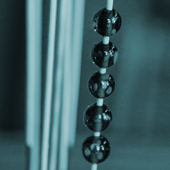

Initially the artisan places large chunks of shattered glass into an open furnace to melt it. He then uses an iron rod to make a loop of molten glass. This molten glass is then transferred to a conical wheel called Khalboot using a long iron pin locally known as “Unaar”.It is also used for maintaining a uniform thickness on all sides of the bangle. A “Khalboot” consists of groves which are marked with different sizes for the bangles. Simultaneously during this process of shaping the bangle on a Khalboot , the bangle is rolled over a powder of golden sparkle also known as “Kirkira” to get the sparkling effect on its surface. This process of coating the surface of bangle is also done by using a glittering strip called “Zari” to form a symmetric pattern on its surface. Finally another layer of molten glass is coiled over the coated surface, and then it is again transferred to the khalboot for subsequent resizing and cooling.

Different designs are also created by the skilled artisan who work in a cluster of 15 to 16 people engaged at a single bhatti or furnace which is maintained at a temperature of around 500 to 600°C.

Purdilnagar itself comprises of 30 to 35 open furnaces producing around 500 to 600 bangles per day, these bangles are liked and worn almost every day as a tradition and it also comes as a style statement in modern times.