Design Resource

Glass Making - Purdilnagar, Uttar Pradesh

Glass - The Exquisite Material

by

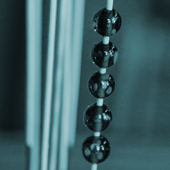

Glass rods manufactured at Firozabad are transported to Purdilnagar for the production of glass beads and bangles. Then they are manually broken into smaller rods which are easier to handle. These smaller rods are then placed on a table which is fitted with a blowing burner and a pedal below. Artisan holds the piece of wire in one hand and the glass rod in the other, then he rotates the glass slowly against the flame of the burner to loop the molten glass around the wire. At his state the molten glass is placed on the mold, which is attached to the presses operated by a pedal, to get the required shape of the glass beads. Once the bead is molded it is then cooled off to be removed from the wire, which are coated with a fine paste of clay, making the glass beads easier to be separated from the wire.