Turning is a machining process typically carried out on a lathe, considered to be the oldest machine tools, and can be of four different types such as straight turning, taper turning, profiling or external grooving. Those types of turning processes can produce various shapes of materials such as straight, conical, curved, or grooved work piece. In general, turning uses simple single-point cutting tools. Soapstone is the basic raw material used in the process of making stone beads. As soapstone is soft, it is easy to carve different varieties of beads. Stone turning is a form of stone working that is used to create stone beads on the lathe. Many intricate shapes can be made by turning stone lathe machine.

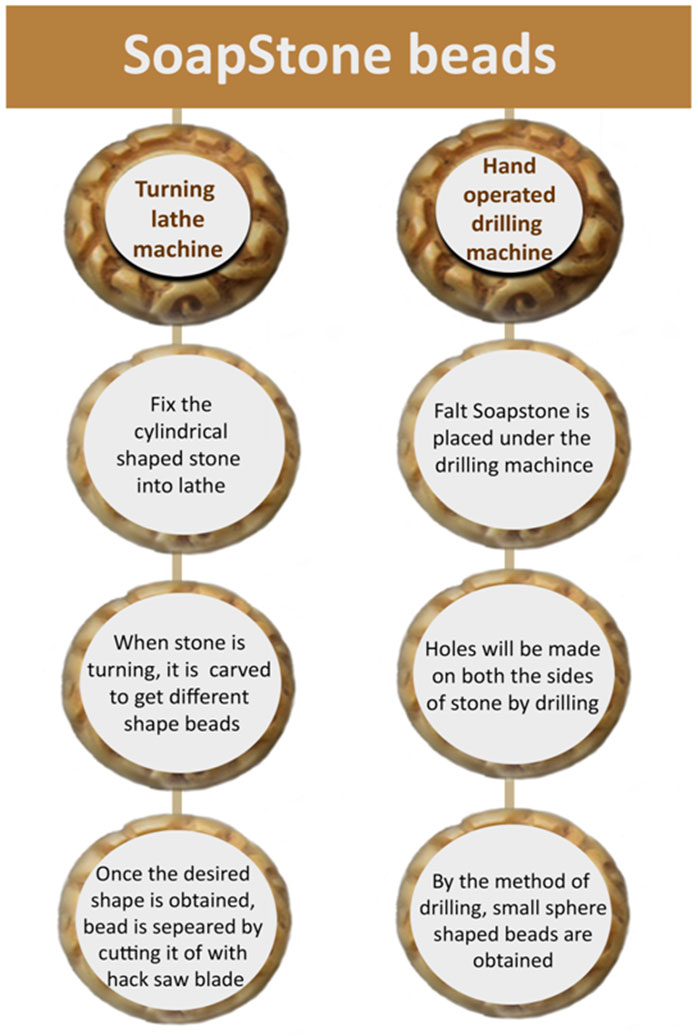

Stone beads are made using 2 methods:

1. Lathe machine

2. Hand operated drilling machine

1. Lathe turning techniques:

Before you begin, you will need to prepare the stone in to cylindrical shape. And that piece of soapstone will be fixed into the lathe machine. Fairly gentle touch is applied while turning, because Soapstone is soft and if more pressure is applied there is a possibility of breakage of stone. The rotational energy of the lathe must be absorbed by the tool, the tool rest and your hands, or by the scraping away of the stone's surface. Too much pressure or a slip with the scraper either stops the lathe, knocks the piece off the faceplate or breaks the stone. Once the bead shape is obtained it is separated with the use of hacksaw blade.

2. Hand operated drilling machine:

Piece of flat soapstone is placed under the drilling machine and on the top of the stone many numbers of holes will be made leaving a little gap between each holes and the same way stone will be reversed and a hole is made on backside. This way holes will be made on both the sides of the stone and by this method proper sphere shaped beads will be obtained.

Flow Chart: