Transport Automobiles

1991-2000

(10 items)

Transport Automobiles1991-2000

(10 items)

(10 items)

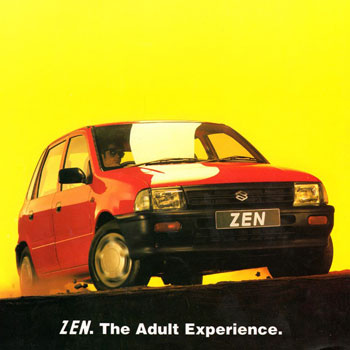

Maruti Suzuki Zen

In the early 1990s, Maruti Udyog Limited (now Maruti Suzuki India Limited) set out to launch a compact and stylish car to cater to the growing Indian middle-class market. The result was the Maruti Suzuki Zen, a car designed and manufactured in India.

Details >>TATA Sierra 1991

The Tata Sierra, launched in 1991, was a pioneering vehicle in Indian automotive history, being the first Indian-designed and manufactured SUV with a 3-door body style and modern features like power windows and air-conditioning—rare at the time. It was also an innovation in Indian automotive history. It had a huge, curved back glass area that gave it a unique appearance and great visibility thanks to its strong, futuristic design. Targeting urban shoppers seeking a balance between comfort and functionality, the design was both elegant and tough. Powered with a 2.0L Peugeot XD88 diesel engine—later updated to a turbocharged version—it was constructed on Tata's X2 chassis, which was adapted from the Tata Telcoline pickup. A significant amount of in-house engineering and fabrication was done during manufacturing at the Tata Motors facility in Pune. Steel panels that had been pressed and welded together made up the Sierra's body, while fibreglass was used for the rear roof cladding and some trim. Interiors featured moulded plastic dashboards, fabric seats, and vinyl-lined trims, giving it a car-like feel inside. The Tata Sierra helped influence the direction of utility vehicles in India and was a daring step towards domestic SUV development.

Details >>TATA Sumo 1994

The Tata Sumo, launched in 1994, was a landmark multi-utility vehicle (MUV) developed entirely in India by Tata Motors, aimed at both civilian and military use. With its spacious cabin, flat hood, and towering stance, the Sumo's boxy, utilitarian design provided enough room for up to nine people. Its practical design placed a strong emphasis on longevity and ease of upkeep, which made it perfect for Indian road conditions. A 2.0L Peugeot XD88 diesel engine powered it; later, Tata's own upgraded engines took its place. Using a ladder-frame chassis, pressed steel body panels, and strengthened underbody structures for strength, the Sumo was constructed at Tata's Pune factory. Depending on the version, the dashboard and interior trims were made of plastics and vinyl, the frame and body were made of mild steel, and the seat upholstery was either vinyl or cloth. Throughout the 1990s and the beginning of the 2000s, government organisations, taxi drivers, and rural families all chose the Tata Sumo because of its sturdy construction, roomy cabin, and affordability.

Details >>Force Trax 1998

The Force Trax (1998) was a rugged multi-utility vehicle developed by Force Motors Ltd., formerly known as Bajaj Tempo Ltd., aimed primarily at rural, semi-urban, and commercial markets. With a lengthy wheelbase that can hold up to 12 passengers or large goods, flat panels, and a high ground clearance, its boxy and functional design prioritised functionality over aesthetics. It had a 2.0- to 2.6-litre diesel engine, produced under licence and renowned for its dependability and ease of maintenance, that was adapted from Mercedes. The vehicle's ladder-frame structure provided structural integrity for both load-bearing and off-road situations. The body panels were made of stamped sheet metal with a strengthened steel frame, and the inside was simple with vinyl upholstery, moulded plastic accents, and few electronic parts to reduce maintenance costs. Its sturdy construction and ease of use made it a favourite among Indian government, law enforcement, and rural transportation users.

Details >>TATA Safari 1998

The Tata Safari (1998) was India's first true SUV designed and developed entirely by an Indian company, marking a milestone for Tata Motors. Featuring a lofty stance, an upright front grille, wide wheel arches, and a side-opening rear door, the Safari's aggressive and muscular look at launch embodied the tough SUV image of the time. It was propelled by a 2.0-litre turbocharged diesel engine that was first purchased from Peugeot and subsequently improved in later models. The ladder-frame chassis on which the vehicle was constructed provided durability for off-road use. A large percentage of the car was locally made in India, with manufacturing taking place at Tata's Pune factory. The Safari's body panels were composed of pressed steel, and its interior had fabric or leatherette seats, injection-moulded plastic accents, and some internal fittings reinforced with glass fibre. It was marketed as a high-end Indian SUV for both urban and outdoor customers, with equipment including air conditioning, power steering, and optional 4WD.

Details >>TATA Indica 1998

The TATA Indica, launched in 1998, was India’s first fully indigenous passenger car designed by Tata Motors. Its design, created in partnership with the Italian design firm IDEA Institute, was a small hatchback with rounded, European-inspired style. At a time when the combination of a diesel engine, a roomy cabin, and fuel efficiency was uncommon in small automobiles, the Indica stood out. Manufacturing took place at Tata’s Pune facility using a high degree of local content. For durability and safety, the body structure was constructed using steel monocoque, while the bumpers, interior panels, and trim were made of plastic and fibre-reinforced materials. With its 1.4L diesel engine (and later gasoline variants), independent suspension, and front-wheel drive, the automobile was reasonably priced and useful. The TATA Indica, which marked Tata Motors' entry into the passenger automobile market, marked a turning point in India's automotive history.

Details >>San Storm 1998

San Motors India Ltd. introduced the San Storm in 1998; it was one of the few convertible sports cars made in India specifically for urban consumers looking for a fun, fashionable car. With its low-slung profile, rounded front, and sporting spirit, the design, which was created in partnership with the Le Mans Group in France, has a distinctly European flair. In contrast to automobiles with metal bodies, the fibreglass-reinforced plastic (FRP) body is lightweight, corrosion-resistant, and less impact-absorbent. The San Storm was powered by a 1.2L petrol engine from Renault that was installed on a tubular steel chassis and coupled to a 5-speed manual gearbox. The majority of the body panels were hand-laid at San Motors' Goa plant, indicating a semi-custom build technique. Despite its distinctive positioning, the car's restricted dealer network, niche appeal, and lack of practicality caused it to struggle in the Indian market; yet, it is still a noteworthy attempt at producing sports cars domestically.

Details >>Rajah Kazwa

India's first MPV attempt was the Rajah (later Kajah) Kazwa, which was introduced in 1998 by Kerala's Rajah Group (which produces Ayurvedic and beedi goods under Rajah Motors). It was two years ahead of Toyota's Qualis. The Kazwa, which was constructed on a specially designed sheet-steel chassis and had a fibreglass body, was heavily influenced by the Renault Espace, as seen by its tall, spacious interior, low window line, and broad frontal glass. It had a 2.0 L Hindustan Isuzu Contessa diesel engine under the hood that produced about 70–72 PS. Hindustan Motors supplied the drivetrain, suspension (independent front, semi-floating rear), brakes, power steering, and gearbox. Dual air conditioning, power steering, windows, central locking, power mirrors, an available sunroof, alloy or wire-spoke wheels, and even a sporty violet-grey dual-tone paint were all features that were ahead of their time. At their Chavakkad, Thrissur factory, some four to seven prototypes were constructed; but, because of problems with regulatory permission and a lack of a sales-service network, they were unable to achieve mass production. The Kazwa, which combines a domestically constructed steel-fibreglass hybrid chassis, European-style styling, and parts from reputable domestic sources, is nevertheless an important if underappreciated pioneer in India's automotive history, even if only a small number of them are left today.

Details >>Hero Honda Splendor

The Hero Honda Splendor (1994) was designed as a highly reliable and fuel-efficient commuter motorcycle, continuing the legacy of the Hero Honda CD100 but with improved styling and ergonomics. It had a long, comfortable seat, flush side panels, a streamlined, aerodynamic fuel tank, and a simple yet stylish headlamp design. With a 97.2 cc air-cooled, 4-stroke engine built on Honda's renowned technology, it produced about 7.4 horsepower and an amazing 80 km/l of mileage, making it one of the most fuel-efficient motorcycles of its era. A tubular double-cradle steel chassis made up the frame, which guaranteed stability and longevity on Indian roads. For weight reduction and corrosion resistance, the majority of the body sections were constructed from pressed steel panels with ABS plastic trims. A balanced ride was offered by telescopic front forks and dual rear shock absorbers, and spoke wheels with drum brakes kept expenses down. Hero Honda's Dharuhera plant in Haryana was used for manufacturing, and a large percentage of the components were locally sourced to guarantee affordability and ease of maintenance. The Splendour is one of the best-selling commuter motorcycles in India because of its simple yet practical design, low maintenance needs, and sturdy construction.

Details >>Bajaj Boxer

The Bajaj Boxer (1997) was introduced as a rugged and affordable commuter motorcycle aimed at rural and semi-urban markets, known for its durability and low running costs. With its boxy fuel tank, flat seat, metal fenders, and sparse body panels, it had a simple yet sturdy design that prioritised functionality above style. Its 100cc, 4-stroke, air-cooled engine, which was created using Kawasaki technology, produced about 7.6 horsepower and offered exceptional fuel efficiency along with ease of maintenance. The body panels were composed of pressed steel with minimal plastic components to increase endurance, and the chassis was a tubular steel double cradle frame designed to endure harsh road conditions. For dependability at a reasonable price, it had spoke wheels, drum brakes, twin rear shock absorbers, and telescopic front forks. The Akurdi and Chakan plants of Bajaj Auto were used for manufacturing, and a large percentage of the parts were locally sourced, guaranteeing affordability and convenient access to spare parts. For Indian riders who needed a reliable daily commuter, the Boxer was a popular workhorse because of its sturdy construction, straightforward mechanics, and great load-bearing ability.

Details >>