Two-wheelers

1951-1960

(2 items)

1961-1970

(2 items)

1971-1980

(3 items)

1981-1990

(5 items)

1991-2000

(2 items)

2001-2010

(6 items)

2011-2020

(5 items)

2021-present

(3 items)

Two-wheelers

1951-1960

(2 items)

Hero Cycles

by Hero Cycles Limited

by Hero Cycles Limited

In the aftermath of independence, India faced significant economic challenges. The bicycle emerged as a vital means of transportation, especially for millions of Indians residing in rural areas. Hero Cycles recognized this need and embarked on a journey to revolutionize the Indian bicycle market.

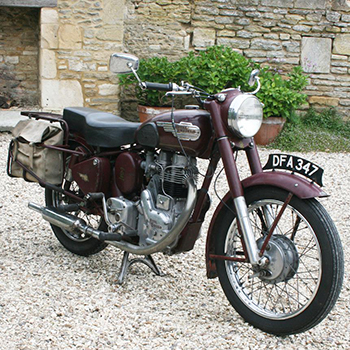

Details >>Royal Enfield Bullet 350

by Enfield India Ltd. (under license from Royal Enfield, UK)

by Enfield India Ltd. (under license from Royal Enfield, UK)

The Royal Enfield Bullet 350 (1955) was one of the earliest models assembled in India by Enfield India Ltd. at Madras (now Chennai), under license from Royal Enfield, UK. With a teardrop fuel tank, hand-painted pinstripes, a sprung single saddle, and a simple tubular steel frame, its design maintained the traditional British aesthetic while remaining stylish and functional. Together with a 4-speed transmission, the 346 cc air-cooled OHV engine produced steady torque that was perfect for Indian road conditions. The manufacturing process started with a combination of imported CKD (completely knocked down) kits before switching to locally made parts with precise machining for the suspension, frame, and engine. It had drum brakes, 19-inch spoke wheels, a swingarm rear suspension with twin shock absorbers (a novel feature at the time), and telescopic front forks. The 1955 Bullet 350 established Royal Enfield's long-standing relationship with India by becoming a symbol of dependability for both military and civilian applications thanks to its strong build, booming exhaust tone, and exceptional low-end torque.

Details >>1961-1970

(2 items)

Jawa 250

by Ideal Jawa India Ltd. (under license from Jawa, Czechoslovakia)

by Ideal Jawa India Ltd. (under license from Jawa, Czechoslovakia)

Jawa Moto produced the Jawa 250 (1961), a Czech motorbike renowned for its sturdy engineering, smooth performance, and exquisite style. It had a 2-stroke, single-cylinder, air-cooled 248cc engine that produced 12–14 horsepower and was mated to a 4-speed gearbox. With a pressed steel backbone and swinging arm rear suspension, the 1961 model's recognisable "C" frame provided a more comfortable ride than rigid frames. With its chrome-finished fuel tank panels, enclosed chain guard, deep valanced fenders, and integrated headlamp and handlebar nacelle, its sleek design gave it a distinctly European look. With its 16-inch or 19-inch spoked rims (depending on the model), drum brakes on both wheels, and a weight of 135–140 kg, the Jawa 250 was both agile and sturdy. The automated oiling system and 2-stroke engine were renowned for their dependability and simplicity of maintenance. Beginning in the mid-1960s, Ideal Jawa Ltd, Mysore, licensed the Jawa 250 for local production, which led to its enormous popularity in India. Its snappy exhaust note, comfy suspension, and smooth acceleration made it a choice among riders for both everyday commuting and touring.

Details >>Rajdoot 175

by Escorts Group (Under technical collaboration with DKW, German)

by Escorts Group (Under technical collaboration with DKW, German)

The Rajdoot 175 (1962) was an Indian motorcycle based on the Polish SHL M11, produced under license by Escort Group (then ESPL). It had a 173 cc, single-cylinder, 2-stroke, air-cooled engine that produced about 7–8 horsepower and was connected to a 3-speed gearbox. The bike's telescopic front forks, two shock absorbers at the back, and tubular steel double cradle frame made for a comfortable yet robust ride. With its straightforward and useful design, deep mudguards, a flat single-piece seat, and a contoured fuel tank, it was ideal for Indian roads and load conditions. The Rajdoot 175 had spoked rims and drum brakes on both wheels, providing simple yet dependable braking. Its torquey 2-stroke engine gave good pulling power, which was especially helpful in rural regions and for transporting big goods, and its lightweight weight of 110–115 kg made it easy to use. Farmers, tradesmen, and rural commuters loved the bike because it was tough, easy to maintain, and could handle harsh terrain. The Rajdoot heritage in India began with the 1962 model, which later developed into the recognisable Rajdoot Standard and, subsequently, the Rajdoot Excel-T versions. It established itself as a reliable workhorse in India for many years by being a symbol of toughness and low operating expenses.

Details >>1971-1980

(3 items)

Bajaj Chetak

by Bajaj Auto Ltd.

by Bajaj Auto Ltd.

The Bajaj Chetak 1972 was an iconic scooter inspired by the Piaggio Vespa Sprint and became a symbol of affordable urban mobility in India. Its design included a large, cosy seat for two, a level floorboard, a rounded front apron, and a traditional curving monocoque steel body. A 2-stroke, single-cylinder, air-cooled 145 cc engine that produced roughly 6–7 horsepower and was connected to a 4-speed hand-shifted gearbox powered the scooter. For basic comfort, it featured a trailing-link front suspension, drum brakes on both wheels, and a kick-starter mechanism. Before Bajaj Auto completely localised production, manufacturing was done in its Akurdi plant near Pune under a licensing arrangement with Piaggio. While parts like the handlebars, rims, and engine casing were built of aluminium alloy to balance weight, the frame and body panels were constructed of pressed steel for durability. The scooter moved on 8-inch steel wheels with tube-style tyres and had a seat with vinyl upholstery and foam padding. In the 1970s, its tough construction, fuel efficiency (around 35 to 40 km/l), and ease of maintenance made it incredibly popular throughout India.

Details >>Yezdi Roadking

by Ideal Jawa (Yezdi)

by Ideal Jawa (Yezdi)

The Yezdi Roadking 1978 was a robust two-stroke motorcycle manufactured by Ideal Jawa Ltd., Mysore, and was based on the CZ 250 motocross bike from Czechoslovakia. It had a 247 cc, air-cooled, single-cylinder, two-stroke engine that produced about 16 horsepower. It was connected to a 4-speed gearbox with a special dual-shift lever, which doubled as a gear lever and a kick-starter. With a flat seat, a teardrop-shaped fuel tank, and little bodywork, the design was muscular but simple, prioritising utility above showmanship. The fuel tank and side panels were composed of pressed steel, and the frame was a double cradle of tubular steel for strength and rigidity. Weight was decreased by using an aluminium alloy for the engine housing and hubs. It featured two 16-inch spoked wheels with drum brakes, telescopic front forks, and twin hydraulic rear shock absorbers. The exhaust had a unique note thanks to its recognisable dual silencers. The Roadking gained popularity among enthusiasts, rally riders, and even the military because of its dependability, exceptional off-road capabilities, and durability.

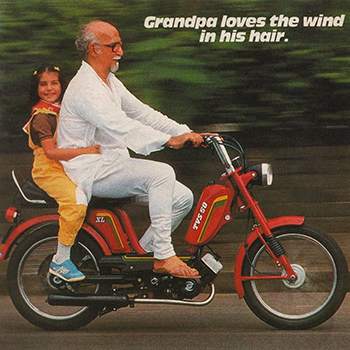

Details >>TVS 50 XL

by TVS Motor Company

by TVS Motor Company

The TVS 50 XL (1980) was a lightweight moped designed for affordability, ease of use, and rugged performance for Indian road conditions. Large, spoked wheels for improved stability on uneven terrain, a flat seat for rider and pillion comfort, and a simple step-through frame with little bodywork were all features of its design. It was incredibly easy to ride without the need for manual gear shifting due to its 49cc, 2-stroke, single-cylinder, air-cooled engine and single-speed automated or centrifugal clutch gearbox. TVS Motor Company handled the manufacturing, localising a lot of parts to keep costs down and guarantee simple maintenance. The fuel tank and panels were constructed of mild steel with enamel paint for corrosion resistance, while the chassis was composed of pressed steel for durability and low weight. To save money and weight, mudguards, side covers, and grips were made of lightweight plastic and rubber components. The moped had a primitive suspension system (rear coil springs and telescopic front forks), few electrical components, and a basic drum brake system. It was a well-liked option in rural and semi-urban India due to its economical design, low maintenance requirements, and fuel efficiency.

Details >>1981-1990

(5 items)

LML Vespa

by LML Ltd. (in collaboration with Piaggio, Italy)

by LML Ltd. (in collaboration with Piaggio, Italy)

An Indian-built imitation of the famous Italian Vespa, the LML Vespa (1984), was created through a technical partnership between Piaggio of Italy and Lohia Machines Limited (LML). It maintained the trademark curving Vespa style while maintaining strength and endurance with the traditional monocoque steel body design, which functioned as both the chassis and exterior skin. It was powered by a 150cc 2-stroke, single-cylinder, air-cooled engine, mated to a 4-speed manual gearbox with the gear selector integrated into the left-hand grip, a typical Vespa feature. For a smooth ride, the scooter had a single-sided trailing-link front suspension, a rear hydraulic shock absorber, and pressed steel wheels with drum brakes. The engine casing was made of die-cast aluminium, the monocoque frame was made of heavy-gauge sheet metal, and the mirrors and trim were made of chrome-plated steel. Smaller components like switchgear and lamp housings were the only ones made of plastic. The LML Vespa maintained the classic Vespa appearance and dependable performance while becoming more reasonably priced by fusing local production with Italian design history.

Details >>Hero Honda CD100

by Hero Honda Motors Ltd. (joint venture between Hero Group and Honda, Japan)

by Hero Honda Motors Ltd. (joint venture between Hero Group and Honda, Japan)

One of the first motorcycles produced by the Hero-Honda joint venture in India was the Hero Honda CD100 (1984), which welcomed a new era of dependable, fuel-efficient commuter bikes. Its design was simple, practical, and aerodynamic; it had a circular headlamp, a flat, single-piece seat for comfort, a short fuel tank with few graphics, and chrome-plated mudguards for a timeless appearance. The bike's 97.2 cc, 4-stroke OHC air-cooled engine prioritises low maintenance and mileage. The body panels, side covers, and fenders were composed of a combination of lightweight plastic and steel to prevent rust, while the double cradle structure was constructed of tubular steel for durability. Chrome was frequently used on the handlebars and exhaust, while mild steel with anti-corrosion coatings was used to construct the chassis and fuel tank. Wheels had spoked steel rims, and rubber parts comprised seat cushions, tyres, and grips. The CD100 was a renowned commuter bike of the 1980s because of its smooth engine, sturdy construction, and good fuel efficiency (around 80–85 km/l).

Details >>Yamaha RX100

by Yamaha (Yamaha in technical collaboration with Escorts Group)

by Yamaha (Yamaha in technical collaboration with Escorts Group)

The Yamaha RX100 (1985) was a legendary two-stroke motorcycle known for its sporty performance, lightweight design, and iconic styling. It had a 98cc, two-stroke, air-cooled engine with reed-valve induction that produced a distinctive exhaust note and rapid acceleration. With a teardrop-shaped fuel tank, chrome-plated front and rear mudguards, a flat, padded seat, a round headlamp, and vintage spoke wheels, its design was simple and timeless. The tank and main body panels were made of pressed steel for strength, while the frame was made of tubular double-cradle steel for rigidity and agility. Side covers were made of lightweight plastic, and the exhaust, engine casing, and handlebar were primarily made of chrome and polished aluminium. The tyres, seat cushions, and grips were all made of rubber, and the wheels included steel rims with wire spokes. With a kerb weight of about 103 kg and good build quality, it was agile but sturdy, gaining a cult following for its dependability, performance, and simplicity of modification.

Details >>Kinetic Honda

by Kinetic Engineering Ltd., India (joint venture with Honda Motor Co., Japan)

by Kinetic Engineering Ltd., India (joint venture with Honda Motor Co., Japan)

A partnership between Kinetic Engineering and Honda Motor Co. produced India's first contemporary gearless scooter, the Kinetic Honda (1985), which brought a new degree of comfort to city commuting. Its 98cc, 2-stroke, air-cooled engine and continuously variable gearbox (CVT) made it incredibly user-friendly by doing away with the necessity for manual gear shifting. With a completely enclosed body, an integrated headlamp, curved panels, and a wide floorboard for comfort and functionality, the design was elegant and modern for its time. While the body panels were primarily composed of plastic-fibre composites to reduce weight and resist corrosion, the underbone chassis was constructed from high-tensile tubular steel for stability and rigidity. Mild steel with anti-rust coatings was utilised for the fuel tank and a few structural components. The engine casing and wheel hubs were made of aluminium alloys, while chrome was used sparingly, only on the exhaust cover and a few trims. The seat was a single, broad unit with vinyl covering and foam cushions. It was groundbreaking, especially for women and first-time riders in the mid-1980s, thanks to its lightweight design (around 95 kg) and electric-start automatic gearbox.

Details >>Bajaj Sunny

by Bajaj Auto Ltd.

by Bajaj Auto Ltd.

The Bajaj Sunny (1990) was a lightweight, gearless moped designed for urban commuting with simplicity and affordability in mind. It had a flat floorboard, a slender body, a simple step-through frame, and small 10-inch wheels for effortless mobility. It was perfect for short city rides because of its 60cc, two-stroke, air-cooled engine, which produced about 2.8 horsepower and could reach a top speed of about 50 km/h. The chassis was constructed using tubular steel for structural strength, while the body panels were mainly composed of pressed steel with some plastic cladding for weight reduction. It featured a trailing arm rear suspension and a basic telescopic front suspension. The Sunny’s design emphasised low cost, low maintenance, and high fuel efficiency, appealing to students and first-time riders. In order to keep the motorcycle affordable and simple to manufacture, Bajaj Auto used locally available parts with little chrome, simple paint jobs and a single-seat arrangement.

Details >>1991-2000

(2 items)

Hero Honda Splendor

by Hero Honda Motors Ltd.

by Hero Honda Motors Ltd.

The Hero Honda Splendor (1994) was designed as a highly reliable and fuel-efficient commuter motorcycle, continuing the legacy of the Hero Honda CD100 but with improved styling and ergonomics. It had a long, comfortable seat, flush side panels, a streamlined, aerodynamic fuel tank, and a simple yet stylish headlamp design. With a 97.2 cc air-cooled, 4-stroke engine built on Honda's renowned technology, it produced about 7.4 horsepower and an amazing 80 km/l of mileage, making it one of the most fuel-efficient motorcycles of its era. A tubular double-cradle steel chassis made up the frame, which guaranteed stability and longevity on Indian roads. For weight reduction and corrosion resistance, the majority of the body sections were constructed from pressed steel panels with ABS plastic trims. A balanced ride was offered by telescopic front forks and dual rear shock absorbers, and spoke wheels with drum brakes kept expenses down. Hero Honda's Dharuhera plant in Haryana was used for manufacturing, and a large percentage of the components were locally sourced to guarantee affordability and ease of maintenance. The Splendour is one of the best-selling commuter motorcycles in India because of its simple yet practical design, low maintenance needs, and sturdy construction.

Details >>Bajaj Boxer

by Bajaj Auto Ltd.

by Bajaj Auto Ltd.

The Bajaj Boxer (1997) was introduced as a rugged and affordable commuter motorcycle aimed at rural and semi-urban markets, known for its durability and low running costs. With its boxy fuel tank, flat seat, metal fenders, and sparse body panels, it had a simple yet sturdy design that prioritised functionality above style. Its 100cc, 4-stroke, air-cooled engine, which was created using Kawasaki technology, produced about 7.6 horsepower and offered exceptional fuel efficiency along with ease of maintenance. The body panels were composed of pressed steel with minimal plastic components to increase endurance, and the chassis was a tubular steel double cradle frame designed to endure harsh road conditions. For dependability at a reasonable price, it had spoke wheels, drum brakes, twin rear shock absorbers, and telescopic front forks. The Akurdi and Chakan plants of Bajaj Auto were used for manufacturing, and a large percentage of the parts were locally sourced, guaranteeing affordability and convenient access to spare parts. For Indian riders who needed a reliable daily commuter, the Boxer was a popular workhorse because of its sturdy construction, straightforward mechanics, and great load-bearing ability.

Details >>2001-2010

(6 items)

Honda Activa

by Honda Motorcycle & Scooter India Pvt. Ltd. (subsidiary of Honda Japan)

by Honda Motorcycle & Scooter India Pvt. Ltd. (subsidiary of Honda Japan)

The Honda Activa (2001), a family-friendly, unisex scooter with a sleek, contemporary appearance, was a revolutionary scooter in India. It had a big, comfy seat, integrated headlamps and indicators, smooth body panels, plenty of under-seat storage, and a simple yet sturdy design. It was equipped with a high-rigidity underbone frame for improved stability and a 102 cc 4-stroke air-cooled engine. High-quality ABS plastic and sheet metal were used to create the body panels, which combined lightweight design and durability. To increase structural strength, high-tensile steel was used to make the frame itself. For improved heat dissipation and weight reduction, aluminium alloy was used to make important sections such as the engine casing, crankcase and gearbox. The scooter included polyurethane foam for the seat cushion, aluminium die-cast wheels, and sturdy rubber floor mats and tyres. The Activa's supremacy in the scooter market began when it was manufactured by Honda Motorcycle & Scooter India (HMSI) and was designed for dependability, ease of handling, and little maintenance.

Details >>Hero Honda Passion

by Hero Honda Motors Ltd.

by Hero Honda Motors Ltd.

The Hero Honda Passion (2001) was a stylish commuter motorcycle designed to offer a balance of reliability, fuel efficiency, and modern aesthetics. It had a stylish yet functional appearance because of its streamlined fuel tank with integrated shrouds, eye-catching body graphics, cosy single-piece seat, and semi-rounded headlight with clear indicators. It was mounted on a tubular double-cradle steel frame for stability and durability, and it was powered by a 97.2 cc 4-stroke, air-cooled engine that was derived from the well-proven CD100 platform. Pressed steel was used for the fuel tank and side panels, while high-impact ABS plastic was used for lightweight strength in body panels such as the side covers and headlamp cowl. For improved heat dissipation, the engine's crankcase and cylinder head were made of aluminium alloy, and the exhaust system was made of mild steel that had been chrome-finished to prevent corrosion. The wheels had rubber tyres on spoked steel rims, while the seat cushions were made of polyurethane foam. Hero Honda Motors Ltd. produced the Passion, one of the most well-liked commuter bikes of its era, by fusing Hero's economical manufacturing with Honda's sophisticated engineering.

Details >>Bajaj Pulsar

by Bajaj Auto Ltd.

by Bajaj Auto Ltd.

The Bajaj Pulsar 2001 was a revolutionary motorcycle that marked Bajaj Auto’s entry into the performance bike segment in India. It had a broad rear stance, an aerodynamic headlight cowl, and a huge fuel tank, giving it a powerful and sporty appearance reminiscent of a streetfighter. The 150cc and 180cc air-cooled, single-cylinder, 4-stroke DTS-i engines, which are renowned for their powerful low-end torque and fuel efficiency, were the two engine options available for the bike. For stability and longevity, the frame was a single downtube, tubular chassis constructed of high-tensile steel. ABS plastic and sheet metal were used to create the fuel tank and side panels, which combined strength and weight reduction. The wheels were alloy rims with spokes or alternative cast wheel versions, and the seat was padded with foam and covered in synthetic leather. Comfort on difficult roads was provided by the suspension components, which comprised dual Nitrox shock absorbers at the back and telescopic forks at the front. With an emphasis on precise machining, die-cast aluminium engine parts, and long-lasting paint finishes to guarantee long-lasting quality, manufacturing was carried out at Bajaj's Chakan plant in Pune using a combination of in-house and vendor-supplied parts.

Details >>Royal Enfield Thunderbird

by Royal Enfield (Eicher Motors)

by Royal Enfield (Eicher Motors)

Launched in 2002, the Royal Enfield Thunderbird 350 represented a major advancement in Enfield's cruiser lineup, catering especially to younger riders looking for a contemporary yet timeless appeal. Wide handlebars, forward-set footpegs, a teardrop-shaped fuel tank, and a low-slung cruiser appearance made for a comfortable riding position that was perfect for long-distance touring. The 350cc air-cooled, 4-stroke, single-cylinder AVL (Anstalt für Verbrennungskraftmaschinen List) lean-burn engine was introduced, improving rider ergonomics with an integrated 5-speed transmission on the left side (a shift from the traditional right-side gearshift). For increased rigidity and riding comfort, a double-cradle frame built of tubular steel was used in the chassis' construction. The fuel tank and the majority of the body panels were composed of steel, which gave it endurance and a vintage appearance. The Thunderbird's unusual "tiger eye" pilot lamp, chrome-plated components, and alloy wheels—a first for Royal Enfield at the time—all contributed to its distinctive character. It was produced in Royal Enfield's Chennai unit and established a new course for the company by striking a balance between vintage style and contemporary dependability and usability.

Details >>TVS Scooty Pep

by TVS Motor Company

by TVS Motor Company

Targeting female riders and beginners, the TVS Scooty Pep was introduced in 2003 as a small, lightweight scooter. With a sleek, unisex design, smooth contours, vivid colours, and a low seat height (about 740 mm) to ensure ease of use for shorter riders, its design placed a strong emphasis on ergonomics, accessibility, and manoeuvrability. A smooth, gearless ride and good fuel efficiency were provided by the scooter's 87.8 cc, air-cooled, 4-stroke motor with CVT (Continuously Variable Transmission). It was lightweight (kerb weight around 95 kg) and durable thanks to its high-tensile steel monocoque frame. Fibre-reinforced composites and ABS plastic made up the majority of the body panels, which improved corrosion resistance and reduced weight. The Scooty Pep, which was produced at the TVS Motor Company's plant in Hosur, Tamil Nadu, gained enormous popularity because of its low cost, simple maintenance, and user-friendly design. It also helped TVS solidify its dominance in the gearless scooter market.

Details >>Royal Enfield Classic 500

by Royal Enfield (Eicher Motors)

by Royal Enfield (Eicher Motors)

The Royal Enfield Classic 500, launched in 2009, marked a significant evolution in the brand's lineup by blending retro styling with modern engineering. Its classic design, which was influenced by post-World War II motorcycles, captured the essence of British motorcycles of the 1950s with its teardrop fuel tank, vintage-style insignia, sprung single saddle, and peashooter exhaust. The Unit Construction Engine (UCE), a 499 cc, single-cylinder, fuel-injected, air-cooled engine that produced smoother performance and complied with contemporary pollution standards, was used for the first time by a Royal Enfield. The Classic 500 was manufactured at Royal Enfield’s facility in Chennai, India, using a combination of a mild steel chassis, aluminium alloy engine components, and sheet metal body panels. Its classic look was enhanced by chrome-plated components, spoke wheels, and conventional finishes; the rider was kept comfortable by leatherette seat coverings and rubber (for footrests and grips). The model, which provided a vintage ride supported by contemporary dependability, was essential to Royal Enfield's worldwide comeback.

Details >>2011-2020

(5 items)

KTM Duke

by KTM Sportmotorcycle AG, Austria (in partnership with Bajaj Auto for India)

by KTM Sportmotorcycle AG, Austria (in partnership with Bajaj Auto for India)

The KTM Duke 200, launched in 2012 in India, was a game-changer in the entry-level performance motorcycle segment with its aggressive naked streetfighter design. Its minimalist bodywork, exposed trellis frame, and sharp lines highlighted its lightweight performance and agility. It was created in Austria by KTM and jointly developed with Bajaj Auto. As part of a global collaboration, it was produced at Bajaj's Chakan plant near Pune. A 199.5 cc single-cylinder, liquid-cooled, fuel-injected engine coupled with a 6-speed transmission gave the bike a powerful performance that made it perfect for sporty and urban riding. A high-tensile steel trellis frame, aluminium alloy wheels, and plastic (ABS) body panels for weight reduction were among the materials utilised. WP's upside-down front forks and a monoshock rear suspension system were used, while disc brakes with optional ABS provided safety. All things considered, the KTM Duke 200 (2012) established a new standard for reasonably priced performance biking by fusing sturdy Indian production with sleek European design.

Details >>Royal Enfield Himalayan

by Royal Enfield (Eicher Motors)

by Royal Enfield (Eicher Motors)

The Royal Enfield Himalayan, launched in 2016, was the brand’s first purpose-built adventure touring motorcycle, designed from the ground up to tackle rugged terrains and long-distance travel. With a large windscreen, split seat, high ground clearance, baggage mounting points, and a digital-analogue instrument cluster with a compass and trip meter—perfect for off-road exploration—it was created by Royal Enfield's design teams in the UK and India. It was powered by a recently created 411 cc air-cooled single-cylinder SOHC engine (LS410), which provided useful torque at low RPMs, allowing versatility in a variety of environments. The bike, which was made at Royal Enfield's plant in Chennai, India, used a half-duplex split cradle steel frame that was created in partnership with Harris Performance (UK). Rubber for grips and foot pegs, polymer plastics for mudguards and side panels, aluminium parts for weight reduction, and steel for the chassis and petrol tank were among the essential materials. The Himalayan, which marked Royal Enfield's debut into the international adventure bike market, stood out for its tough simplicity, fusing comfort with durability.

Details >>Hero Xpluse

by Hero MotoCorp Ltd.

by Hero MotoCorp Ltd.

India's first reasonably priced dual-sport adventure motorcycle, the Hero XPulse 200, was introduced in 2019 and is built for both off-road capability and on-road comfort. It has a tough, go-anywhere appearance with useful trail protection due to its high-mounted front mudguard, long-travel suspension, elevated exhaust, knuckle guards, and bash plate. Lightweight and adaptability are key components of the design, which was created internally at Hero MotoCorp's CIT (Centre of Innovation and Technology) in Jaipur. It has a single-cylinder, air-cooled, 199.6 cc engine that is fuel-injected for efficiency and pollution control. The XPulse is manufactured at Hero’s production facility in Haridwar, India, using a diamond-type steel frame for durability and aluminium components like the swingarm for reduced weight. Rubber components provide comfort and traction, while ABS and polypropylene plastic body panels are utilised for durability and economy. The XPulse 200 established a standard for accessible adventure riding in India with its off-road ergonomics, Bluetooth-enabled digital console, and simple yet practical design.

Details >>Ather 450X

by Ather Energy Pvt. Ltd.

by Ather Energy Pvt. Ltd.

The 2020 Ather 450X was designed and built in India; it was first manufactured in Ather Energy's Bengaluru plant before being expanded at its Hosur, Tamil Nadu, plant, which started production in early 2021. Its precision-machined hybrid chassis strikes a compromise between lightweight stiffness, crash safety, and battery shielding by integrating cast-aluminium main frame components with selective high-strength steel reinforcing. With the 2.9 kWh/21700 cell pack enclosed within a Tesla-inspired aluminium structure integrated in the frame for enhanced thermal and impact protection, the chassis design also serves as the battery casing. Sharp, contemporary style and panelwork are highlighted by flush-fitting body panels, a lattice-exposed aluminium trellis frame that is visible beneath the seat sections, and streamlined LED lighting (tail, headlights, and indicators) that combines durability and minimalism. At debut, the fit-and-finish received recognition for its high-end details like aluminium mirror stalks and number-plate brackets, clean edges, matte paint options (especially Space Grey), and sturdy construction. Reviewers pointed out that the scooter's thick aluminium safety margins contribute to its relatively heavy curb mass (~108 kg), but this was done on purpose to preserve the NMC battery chemistry and improve structural stiffness without sacrificing manoeuvrability.

Details >>Jawa Perak

by Classic Legends Pvt. Ltd. (licensed from Jawa, owned by Mahindra Group)

by Classic Legends Pvt. Ltd. (licensed from Jawa, owned by Mahindra Group)

Jawa Motorcycles introduced the Jawa Perak (2020), a factory-custom bobber motorbike with minimalist style intended to create a retro-modern look. It has a unique, rebellious appearance reminiscent of vintage bobbers thanks to its low-slung stance, matte black finish, floating single seat, and bar-end mirrors. A 334 cc single-cylinder, liquid-cooled DOHC engine that produces about 30.64 PS and 32.74 Nm of torque and is connected to a 6-speed gearbox powers the motorbike. Its double cradle tubular frame and mono-shock rear suspension, which is exclusive to Jawas, enable a more streamlined rear profile. The front is equipped with dual-channel ABS disc brakes at both ends and telescopic forks. Precision engineering is ensured by the Mahindra-owned factory in Pithampur, Madhya Pradesh, where manufacturing is conducted. A steel frame, metal body panels, aluminium engine parts, and rubberised and leather-like seat coverings are some of the materials that give it a tough yet elegant look.

Details >>2021-Present

(3 items)

Royal Enfield Classic 350

by Royal Enfield (Eicher Motors)

by Royal Enfield (Eicher Motors)

The Royal Enfield Classic 350 (2021) is a modern iteration of the iconic retro cruiser, blending vintage aesthetics with updated engineering. Its teardrop-shaped fuel tank, circular headlamps with pilot lights, peashooter exhaust, and spoked or alloy wheels are all hallmarks of its neo-retro style, which was influenced by British bikes built after World War II. Built on the new J-series platform, the 2021 model offers a more refined and high-quality ride. Compared to the earlier UCE engine, the 349cc air-oil-cooled single-cylinder engine produces smoother performance and less vibration. The bike is manufactured in Royal Enfield's Oragadam facility in Chennai, India, using state-of-the-art production lines equipped with precision machining, robotic welding, and stringent quality control. The frame and body panels are made of steel, the engine parts are made of aluminium alloy, and the grips, footrests, and switchgear are made of rubber and plastic composites. In addition, the Classic 350 (2021) maintains its classic style while adding dual-channel ABS, electronic fuel injection (EFI), and a semi-digital instrument cluster for increased safety.

Details >>Ola S1 Pro

by Ola Electric Mobility Pvt. Ltd.

by Ola Electric Mobility Pvt. Ltd.

The Ola S1 Pro (2021) is a sleek and futuristic electric scooter designed with smooth monocoque body panels, integrated twin-pod LED headlamps, and a wide touchscreen dashboard, giving it a modern yet minimalist aesthetic. It emphasises both form and function with its alloy wheels, telescopic front suspension, and monoshock rear suspension, all mounted on a tubular steel frame. With a certified range of 181 km and a top speed of 115 km/h, the scooter is powered by a 3.97 kWh NMC (Nickel-Manganese-Cobalt) lithium-ion battery and a mid-drive IPM electric motor. It is manufactured at the highly automated Ola FutureFactory in Krishnagiri, Tamil Nadu, which has internal battery and motor manufacturing facilities as well as robotic assembly lines. The frame and body are made of steel and sheet metal, the battery connectors are made of aluminium, the battery housing is made of UV-bonded plastic, and some of the external panels have glass-reinforced polymer components. The S1 Pro blends advanced EV technology with elegant industrial design to deliver a high-performance, eco-friendly urban mobility solution.

Details >>Yulu Dex

by Yulu Bikes Pvt. Ltd.

by Yulu Bikes Pvt. Ltd.

The Yulu Dex, launched in mid-2021, was purpose-built as an ultra-light, low-speed electric two-wheeler tailored for short-mile deliveries of food, groceries, and medicines. It is categorised as a low-speed EV, which means that drivers do not require a driver's license, and has a top speed of 25 km/h and a certified range of about 60 km per charge. Its design includes a small, narrow chassis that is ideal for navigating through crowded city streets and an integrated rear cargo rack that can safely hold up to 12 kg of delivery products. An ergonomically low seat height and increased cushioning provide comfort for gig workers who ride their bikes for extended periods of time in crowded and uneven roadways. The Dex is thought to have a tubular steel chassis or frame with sheet-metal body panels, ensuring durability in delivery circumstances, even though specific material specifications were not made public. A lithium-ion battery pack powers its electric drivetrain. It is designed for quick swaps using a push-fit mechanism behind the seat, enabling seamless use with Yulu's "Yulu Max" charging and battery swap network across Bengaluru, Delhi, and Mumbai. Yulu's app's real-time IoT connection through smart battery and vehicle systems allows for charge, health, fault, and ride telemetry monitoring, promoting preventive maintenance and almost zero downtime.

Details >>